The current trend of reducing energy costs will make you think about installing alternative solutions. Large industrial sites that use electric forklifts are equipped with stationary charging stations that work in non-stop mode. The use of solar panels in conjunction with the solutions of Tavrida Electric can become an additional source of charging electric forklifts.

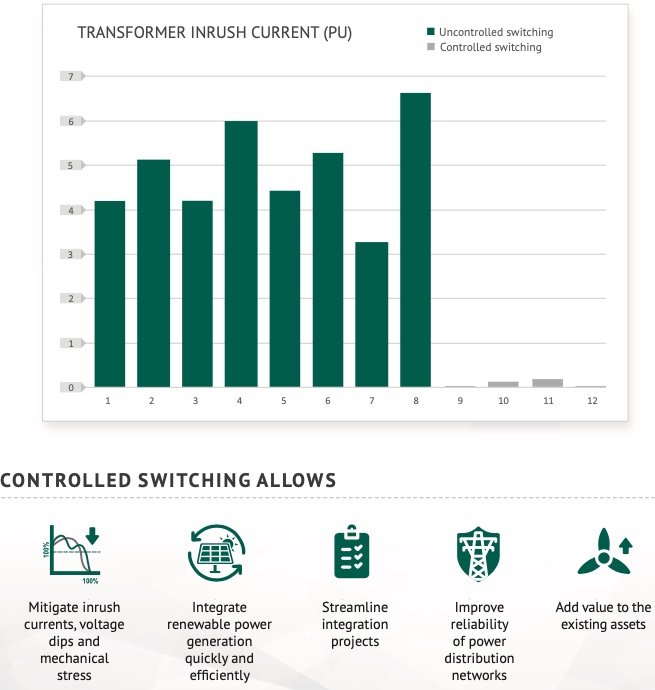

The routine switching of grid connected transformers interfacing distributed generation produces a lot of disturbances, such as inrush current and voltage dips.

In many cases grid operators require system integrators to comply with very strict inrush current requirements, sometimes below 1 p.u. Such requirements tend to increase the project cost, lead time and in many cases result in project cancellation.

The solution for the problem is controlled switching.

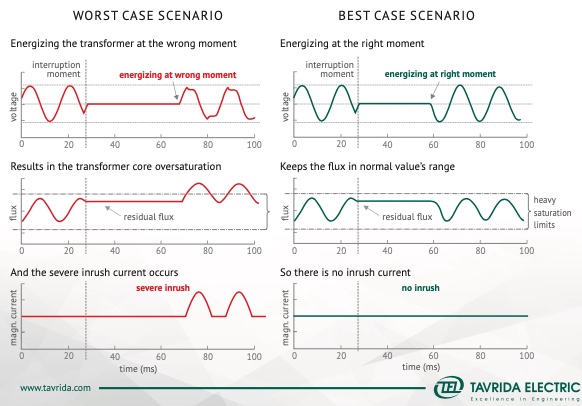

Controlled switching (sometimes also referred as point on wave switching) is a technique of switching the electrical circuit on a specific point of a sin-wave – voltage or current, to minimize:

- Switching transients and associated inrush currents;

- Voltage disturbances;

- Re-strikes and arc re-ignitions.

Controlled Switching Allows

- Mitigate inrush currents, voltage dips and mechanical stress;

- Integrate renewable power generation quickly and efficiently;

- Streamline integration projects;

- Improve reliability of power distribution networks;

- Add value to the existing assets.

- Indoor Tavrida Electric switchgear/outdoor vacuum circuit breakers with single phase operation.

- Vizimax SynchroTeq® Control Switching Device (CSD).

Comments

Post a Comment